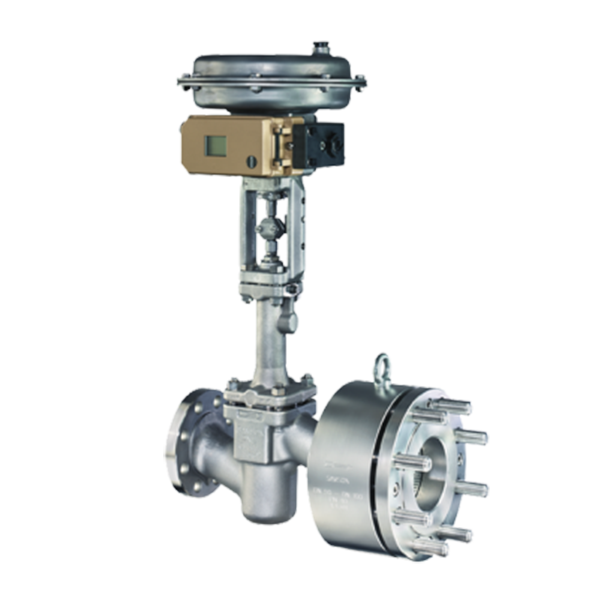

Description

Size: 1/2″ to 32″

ANSI Class: 150 to 2500

Std. Materials: Forged Steel, Forged Stainless Steel, (Special Materials on Request)

Temperature Range: -58 to 750oF (-50 to 400oC)

The Type 3381 Downstream Silencer provides noise attenuation by acting as a fixed restriction. The silencer system introduces a backpressure downstream of the valve that raises the pressure of the medium flow at the valve outlet, thus allowing the 3381 silencer to provide the final process pressure reduction to the system.

As a result of this additional pressure reduction stage, the sound pressure level is reduced. In applications using compressible media, it additionally lowers the flow velocity at the valve outlet.

FEATURES & BENEFITS

- Suitable for Liquid, Gas, and Vapor Service

- In liquid service, results are noise reduction and cavitation reduction.

- In gas and vapor service, results are noise reduction, valve outlet velocity reduction, and valve size reduction.

- Pressure reduction can be in excess of 100 psi per plate, a five-stage silencer design allows for pressure drops greater than 500 psi.

Type 3381 Downstream Silencer is offered in several designs:

- Wafer single plate – placed before or after pipeline expansion

- Two wafer single plates – placed before and after pipeline expansion

- Flanged single plate – placed before or after pipeline expansion

- Flanged single plate with multiple stages – placed before or after pipeline expansion

- Multi-stage plates in body housing – placed between valve outlet and expanded downstream pipe

Reviews

There are no reviews yet.